Edge vs Cloud Computing in IIoT: A Guide for Manufacturers

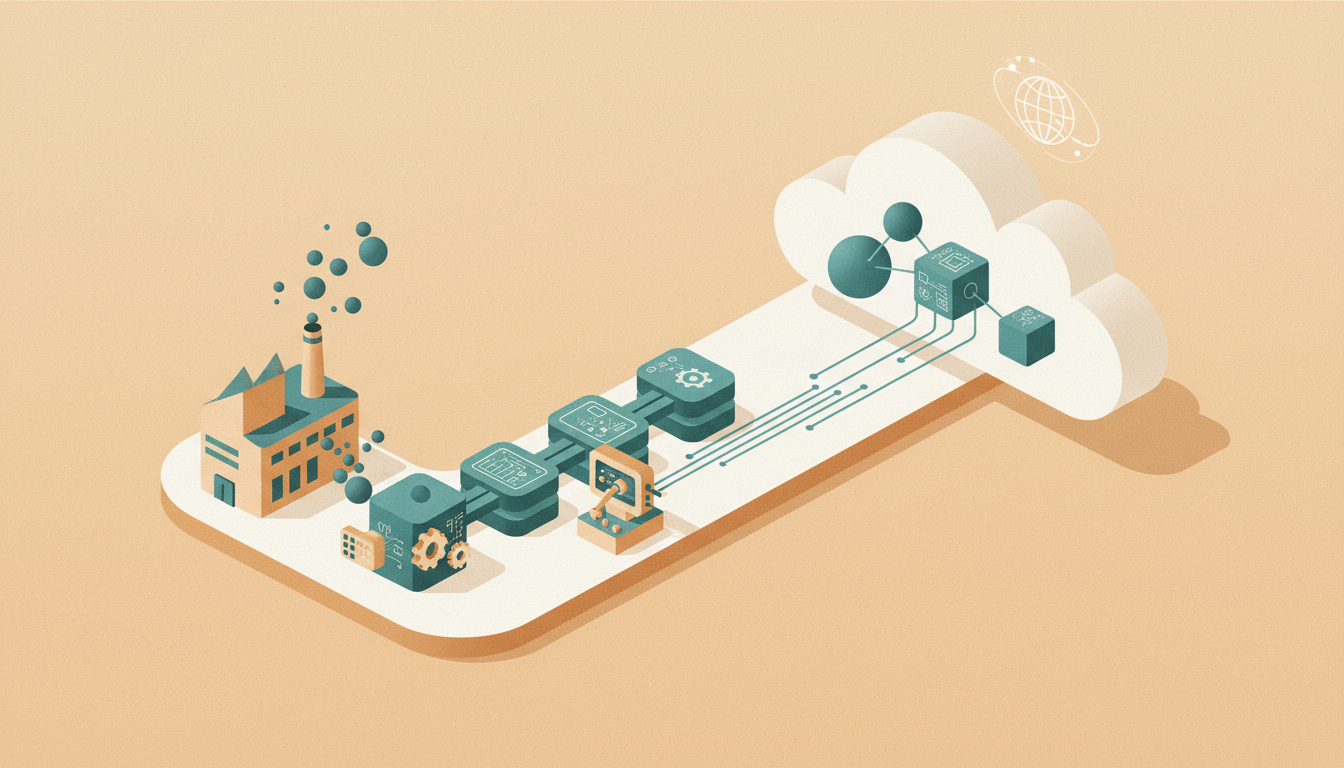

Imagine a factory floor where thousands of sensors on robotic arms, conveyors, and assembly machines generate a continuous stream of data. This data holds the key to unprecedented efficiency, but if it takes seconds or minutes to travel to a distant data center for analysis, a critical machine could fail or a defective product could be produced before anyone knows something is wrong. This latency-induced inefficiency is the core problem many manufacturers face as they digitize their operations. The struggle to choose between edge computing and cloud computing for an Industrial Internet of Things (IIoT) strategy often leads to suboptimal performance, unexpected costs, and missed opportunities for real-time optimization.

This guide cuts through the complexity. You will gain a clear, practical understanding of what edge and cloud computing each bring to an IIoT deployment. More importantly, you’ll learn how to strategically deploy them,separately or together,to build smarter, faster, and more resilient manufacturing systems that drive tangible results on your factory floor.

What is Edge Computing in Industrial IoT?

At its core, edge computing in IIoT is about processing data right where it is created,on the "edge" of the network, physically close to the machines, sensors, and processes on your factory floor. Instead of sending every byte of raw data to a centralized cloud server, edge computing filters, analyzes, and acts on that data locally. This paradigm shift is fundamental for manufacturing environments where milliseconds matter and consistent connectivity cannot be guaranteed.

The core principle is local data processing. A temperature sensor on an injection molding machine doesn't need to send a constant "all is well" signal to a cloud server thousands of miles away. Instead, an edge device locally monitors that stream. It only communicates with the cloud if the temperature exceeds a predefined threshold, signaling a potential fault. This approach conserves network bandwidth, reduces costs, and, most critically, enables real-time analytics and control.

For manufacturers, this translates directly to improved operational efficiency. Anomalies can be detected and addressed instantaneously, preventing minor issues from cascading into hours of costly downtime. It enables faster, autonomous decision-making at the machine level, from adjusting robotic arm pressure to rejecting a defective part on the spot.

Core Components of Edge Computing

An effective IIoT edge setup is built on a hierarchy of hardware and software components working in concert. Understanding these pieces is key to implementation.

- Sensors and Actuators: These are the foundational data sources and action-takers. Vibration sensors, vision cameras, PLCs (Programmable Logic Controllers), and torque sensors generate the raw operational data.

- Edge Devices/Gateways: This is the "brain" at the edge. These are hardened industrial computers or specialized modules that sit between the sensors and the broader network. They perform the initial heavy lifting: aggregating data from multiple sources, running lightweight algorithms for filtering and preliminary analysis (e.g., Fast Fourier Transform for vibration data), and translating between disparate industrial protocols (like Modbus, OPC UA) to a common language like MQTT.

- Edge Servers/Nodes: For more computationally intensive tasks, more powerful servers can be deployed locally within a factory or plant. These can handle complex analytics, machine learning inference for predictive maintenance models, or real-time video analytics for quality inspection.

- Lightweight Software & Algorithms: The software stack is optimized for resource-constrained environments. This includes containerized applications (e.g., Docker), lightweight analytics platforms, and pre-trained AI models designed to run efficiently on edge hardware without needing constant cloud connectivity.

How Edge Computing Works in Practice

Let's trace the data flow in a real-world scenario: a robotic welding station on an automotive assembly line.

- Data Generation: High-speed cameras and laser sensors mounted around the welding robot capture thousands of images and depth measurements per second of each weld seam.

- Local Processing: This massive stream of data is fed directly into an edge server positioned on the factory floor. On this server, a computer vision algorithm analyzes each image in real-time.

- Instantaneous Decision: The algorithm checks for defects,cracks, porosity, or incorrect bead geometry. If a defect is detected within milliseconds, the edge system can immediately signal the line controller to flag that specific car body for rework or halt the station before more defective welds are produced.

- Selective Cloud Communication: Only the summary data,"Weld Station #4: 99.7% pass rate, 2 defects found and handled at 14:23",along with compressed snippets of the defect images for root cause analysis, are sent to the cloud. The terabytes of raw video data never leave the factory.

This practice of local analysis and immediate action is what makes edge computing indispensable for quality control systems, safety monitoring, and any process where latency is the enemy of quality and safety.

What is Cloud Computing in Industrial IoT?

While edge computing handles the immediate, cloud computing in IIoT provides the centralized brain for long-term strategy, deep learning, and enterprise-wide insight. It involves storing, managing, and processing data on remote servers accessed via the internet. For manufacturers, the cloud is not a replacement for the edge but a powerful complement that excels at tasks requiring vast historical context, immense scalable resources, and cross-facility correlation.

The primary benefit is scalability. Need to analyze five years of production data from three different factories to identify a subtle seasonal quality trend? The cloud can spin up the necessary computational power on-demand. It is inherently cost-effective for storing and processing large datasets over time, as you pay for what you use rather than maintaining costly, underutilized on-premise data centers. It enables advanced analytics, like training complex machine learning models for predictive maintenance, which require datasets far larger than any single edge node could hold.

Common use cases include long-term historical data analysis for process optimization, predictive maintenance model training and refinement, supply chain optimization by integrating ERP and MES data, and seamless system integration across a global manufacturing footprint.

Cloud Service Models for IIoT

Understanding the different cloud service models helps in selecting the right tools for your manufacturing goals.

- Infrastructure as a Service (IaaS): This is the foundational layer. You rent virtualized computing resources,servers, storage, networking. In IIoT, a manufacturer might use IaaS (like AWS EC2, Microsoft Azure VMs) to host their own custom-built data historian or analytics application. You manage the OS and software, while the provider manages the hardware.

- Platform as a Service (PaaS): This provides a development and deployment environment. It's ideal for teams building IIoT applications without wanting to manage the underlying infrastructure. For example, using Google Cloud's AI Platform or Azure IoT Hub to develop, train, and deploy a machine learning model that predicts machine failure from aggregated edge data.

- Software as a Service (SaaS): This is the finished application you access via a web browser. In manufacturing, this includes cloud-based MES (Manufacturing Execution Systems), CMMS (Computerized Maintenance Management Systems), or analytics dashboards like Tableau Online. A factory manager logs in to see real-time OEE (Overall Equipment Effectiveness) dashboards that pull data from both edge and cloud repositories.

Cloud Computing Workflow in Manufacturing

The cloud acts as the central aggregator and intelligent analyzer. Here’s a typical workflow:

- Data Aggregation: Summarized and critical data from hundreds of edge devices across multiple production lines and factories are securely transmitted to the cloud platform.

- Data Lake Ingestion: This data flows into a centralized data lake,a vast repository storing structured and unstructured data in its raw form.

- Advanced Processing & Analytics: Here, powerful cloud resources perform tasks impossible at the edge. This includes correlating machine vibration data from a plant in Germany with ambient temperature data and supplier component batch information to identify the root cause of a recurring bearing failure.

- Insight Generation & Action: The results of this analysis are visualized in executive dashboards, used to retrain and improve the predictive models, and can send updated parameters or new "rules" back down to the edge devices. For instance, the cloud-based model might discover a new early-warning signature for pump failure and push a updated algorithm to all relevant edge gateways worldwide.

Key Differences: Edge Computing vs Cloud Computing in IIoT

Choosing between edge and cloud isn't an "either/or" question for most modern manufacturers; it's about understanding their distinct strengths and applying them strategically. The table below summarizes the core differences:

| Feature | Edge Computing | Cloud Computing |

|---|---|---|

| Primary Role | Real-time control, immediate response, data filtration. | Long-term storage, deep analysis, enterprise-wide insight. |

| Data Processing Location | At or near the source (factory floor). | In remote, centralized data centers. |

| Latency | Extremely low (milliseconds). Critical for closed-loop control. | Higher (seconds to minutes). Acceptable for non-critical analytics. |

| Bandwidth Usage | Minimal. Transmits only essential, processed data. | High. Can handle large raw data transfers for analysis. |

| Connectivity Dependency | Can operate autonomously during network outages. | Heavily dependent on stable, high-bandwidth internet. |

| Security Focus | Physical security of devices, local data sovereignty. | Cybersecurity, encryption in transit/at rest, advanced threat detection. |

| Scalability | Limited by local hardware. Scaling requires deploying more devices. | Virtually unlimited, elastic scaling on-demand. |

| Cost Model | Higher upfront capital expenditure (CapEx) for hardware. | Operational expenditure (OpEx) based on subscription and usage. |

| Best For | Time-sensitive decisions, safety systems, bandwidth-constrained locations. | Big data analytics, model training, collaboration across sites, archival. |

Latency and Real-time Processing

Latency,the delay between data generation and actionable insight,is the most critical differentiator. Edge computing minimizes delays to milliseconds, which is non-negotiable for certain manufacturing tasks.

- Example - Robotic Control: In a high-speed pick-and-place application, a vision system must identify a component's orientation and communicate precise coordinates to a six-axis robot arm. A round-trip to the cloud could introduce 100+ milliseconds of delay, causing the robot to miss its target. An edge device processes the image locally and sends the command in under 10 milliseconds, ensuring perfect, rapid synchronization.

- Example - Safety Monitoring: A light curtain sensor detecting an operator's hand in a dangerous area must trigger an emergency stop immediately. Relying on cloud processing for this decision is impractical and unsafe. The logic must reside at the edge.

Data Security and Privacy

Security is paramount in IIoT, but the approach differs.

- Edge Security: The focus is on local data handling and physical security. Sensitive data, such as proprietary production formulas or real-time quality defect images, never traverses the public internet, reducing the attack surface. This addresses data sovereignty concerns, as information stays within the factory's geographic boundary. The challenge is securing potentially thousands of distributed physical devices from tampering.

- Cloud Security: Major cloud providers invest billions in cybersecurity, offering robust, enterprise-grade protections. Data is encrypted both in transit and at rest. However, transmitting sensitive operational data over networks always carries a perceived risk. A comprehensive strategy often involves using the edge to anonymize or summarize sensitive data before sending it to the cloud.

Cost and Resource Management

The financial implications of each approach are distinct and can significantly impact ROI.

- Edge Computing Costs: Characterized by higher initial investment (CapEx) for purchasing and deploying industrial-grade edge hardware, gateways, and on-premise servers across the facility. However, it leads to lower ongoing operational costs by drastically reducing the volume of data transmitted (saving on bandwidth) and can prevent extremely costly unplanned downtime through real-time intervention.

- Cloud Computing Costs: Follows a pay-as-you-go operational expenditure (OpEx) model. You avoid large upfront hardware costs but incur recurring fees for data storage, computing power, and services. This is highly scalable and cost-effective for variable workloads but can become expensive if raw, high-volume sensor data is streamed to the cloud continuously without edge-level filtration.

Applications of Edge and Cloud Computing in Modern Manufacturing

The true power of IIoT is realized when edge and cloud are applied to solve specific manufacturing challenges. Here are two detailed case studies.

Case Study: Predictive Maintenance with Edge Computing

Problem: A manufacturer of packaging machinery faced unexpected bearing failures in high-speed rotary cutters, causing unplanned downtime of 8-10 hours per failure and significant scrap material.

Edge Solution: Vibration sensors were installed on each cutter's drive shaft. An edge gateway nearby continuously sampled the vibration data and ran a lightweight algorithm to calculate the Fast Fourier Transform (FFT), converting raw vibration into a frequency spectrum.

How it Worked: The edge device was programmed to monitor the amplitude at specific harmonic frequencies known to indicate bearing wear. Under normal conditions, it simply sent a "healthy" status pulse every hour. When the amplitude at a critical frequency began to trend upward, crossing a pre-set threshold, the edge device performed two actions in real-time:

1. It triggered a local alert on the HMI (Human-Machine Interface), notifying the technician of the specific machine and component at risk.

2. It began streaming high-resolution, time-stamped vibration data for that specific machine to the cloud for deeper analysis.

Result: Failures shifted from "unplanned" to "planned." Maintenance could be scheduled during the next planned tooling change, eliminating disruptive downtime. The smart factory used the edge for immediate detection and the cloud for long-term trend analysis of the failure data to improve future designs.

Case Study: Cloud-Based Analytics for Supply Chain

Problem: An automotive parts supplier struggled with inventory imbalances and logistics delays across its global network of 12 factories, leading to production stoppages and air freight emergencies.

Cloud Solution: The company implemented a cloud-based supply chain analytics platform. This platform ingested data from multiple sources:

* Real-time production completion data from edge systems at each factory.

* Inventory levels from Warehouse Management Systems (WMS).

* Shipping and logistics data from partners.

* Demand forecasts from the sales ERP system.

How it Worked: The cloud platform used its immense processing power to run optimization algorithms on this global dataset. It could simulate scenarios, predict potential shortages weeks in advance, and identify the most efficient shipping routes. For example, it might identify that a delay in component shipments from Malaysia to a factory in Poland could be mitigated by temporarily increasing production and transferring semi-finished goods from a sister factory in the Czech Republic.

Result: The cloud provided the holistic, cross-enterprise visibility that individual edge computing nodes at each factory could not. This led to a 15% reduction in inventory carrying costs, a 25% decrease in expedited freight charges, and a more resilient, responsive supply chain.

Choosing the Right Strategy: Edge, Cloud, or Hybrid for Your IIoT Needs

For most manufacturers, a hybrid edge-cloud architecture delivers the optimal balance, leveraging the strengths of both. The key is making a strategic choice based on your specific needs.

Factors to Consider When Choosing

Use this framework to evaluate your manufacturing scenarios:

- Latency Requirement: Does the application need a response in milliseconds (e.g., machine control, safety)? → Leans Edge. Is a response in seconds/minutes acceptable (e.g., shift reporting, trend analysis)? → Leans Cloud.

- Data Volume & Bandwidth: Are you generating massive, continuous data streams (e.g., high-speed video)? → Use Edge to filter and reduce. Is your data episodic or summarized? → Cloud can handle it efficiently.

- Connectivity Reliability: Is your factory in a location with poor or expensive internet? → Edge is essential for autonomy. Do you have robust, reliable connectivity? → Cloud becomes more viable.

- Data Sensitivity & Sovereignty: Does your data include highly sensitive IP or face strict local data residency laws? → Edge processing keeps it local. Is the data less sensitive or anonymized? → Cloud analytics are powerful.

- Cost Structure Preference: Do you have capital for upfront hardware investment and IT staff for management? → Edge CapEx model. Do you prefer a predictable, scalable operating expense? → Cloud OpEx model.

- Analytical Complexity: Does the decision logic involve simple thresholds or pre-trained models? → Can run at the Edge. Does it require correlating years of data across multiple systems or training new AI models? → Requires Cloud power.

Steps to Deploy a Hybrid IIoT System

Deploying a hybrid system is a phased journey, not a one-time project.

- Planning & Assessment: Define clear use cases (e.g., "reduce unplanned downtime on CNC line #3 by 30%"). Map your data sources, network infrastructure, and legacy systems. Use the factor list above to decide which parts of the solution belong at the edge and which in the cloud.

- Hardware & Platform Selection: Choose industrial-grade edge devices (gateways, servers) that match your environmental needs and compute requirements. Select a cloud platform (AWS IoT, Azure IoT, Google Cloud IoT) that offers the analytics services and integration tools you need.

- Pilot Deployment: Start small. Implement the hybrid solution on a single production line or for one specific use case (like the predictive maintenance case study). This allows you to test the architecture, data flow, and ROI in a controlled environment.

- Data Integration & Application Development: Establish a clear data pipeline. Define what raw data is processed at the edge, what summary/alert data is sent to the cloud, and how insights from the cloud (like updated ML models) are fed back to the edge. Develop or configure the necessary applications and dashboards.

- Scale & Continuous Monitoring: Once the pilot proves successful, develop a roll-out plan to scale across other lines and facilities. Continuously monitor system performance, security, and business outcomes, refining the balance between edge and cloud processing as needed.

Future Trends: Watch for AI at the edge, where more powerful, efficient chips will allow complex AI inference to run locally. The integration of 5G will provide the high-speed, low-latency backbone that can further blur the lines between edge and cloud, enabling more dynamic workload distribution.

Conclusion

The journey toward a smarter factory isn't about choosing between edge computing and cloud computing. It's about strategically assigning the right workload to the right layer. Edge computing is ideal for real-time, latency-sensitive tasks that demand immediate action,it's the nervous system of your IIoT, reacting reflexively to keep operations smooth and safe. Cloud computing offers unparalleled scalability and advanced analytics,it's the strategic brain, finding deep insights and optimizing the entire enterprise over the long term.

For the vast majority of modern manufacturers, a hybrid approach delivers the best results. Use the edge to handle the urgent, filter the noise, and ensure resilience. Use the cloud to find meaning, train intelligence, and connect the dots across your global operations. By understanding and implementing this symbiotic relationship, you can build IIoT systems that are not just connected, but truly intelligent and transformative.

Key Takeaway: Edge computing is ideal for real-time, latency-sensitive tasks in IIoT, while cloud computing offers scalability and advanced analytics; a hybrid approach often delivers the best results for modern manufacturing.

Subscribe to manufacturenow for more insights on optimizing your manufacturing processes with the latest technologies.

Frequently Asked Questions (FAQs)

1. Can I start with just cloud computing for my IIoT project to keep things simple?

You can, but you may quickly encounter limitations. Streaming all raw sensor data to the cloud can become prohibitively expensive due to bandwidth costs and cloud service fees. More critically, any application requiring instant action (like stopping a machine for safety) will suffer from latency. It's often more effective to start with a small-scale hybrid pilot to understand the data flow and costs.

2. Is edge computing more secure than the cloud?

It's a different type of security. Edge computing can be more secure for data sovereignty as sensitive information stays on-premises. However, you are responsible for physically securing thousands of devices. The cloud offers world-class cybersecurity infrastructure but requires you to trust a third party and secure data in transit. A hybrid approach lets you keep your most sensitive operational data at the edge while using the cloud's security for less sensitive, aggregated analytics.

3. How do I manage and update software on hundreds of edge devices?

This is a crucial operational consideration. Look for edge computing platforms and hardware that support over-the-air (OTA) updates and centralized device management. Leading cloud IoT platforms (like Azure IoT Edge, AWS IoT Greengrass) provide tools to remotely deploy, monitor, and update software containers on your edge device fleet from a single dashboard, similar to how you manage cloud applications.

Written with LLaMaRush ❤️