Digital Thread in Manufacturing: 2026 Ultimate Guide for Seamless PLM

Imagine a manufacturing process where every piece of data, from the initial spark of an idea to the final bolt tightened on the assembly line, flows in a single, unbroken stream. There are no frantic searches for the latest CAD file, no mismatched BOMs causing production halts, and no guesswork in the supply chain. This seamless flow of information isn't a futuristic dream,it’s the reality enabled by digital thread technology. Yet, in today’s manufacturing landscape, data silos and disconnected systems are the norm, leading to costly inefficiencies, frustrating errors, and painful delays in product lifecycle management (PLM).

By the end of this guide, you'll have a firm grasp on what the digital thread is, how it fundamentally differs from related concepts like the digital twin, and the tangible benefits it delivers. Most importantly, you'll have a clear, step-by-step framework for evaluating and implementing this transformative approach in your own operations to achieve superior manufacturing outcomes.

What is Digital Thread Technology?

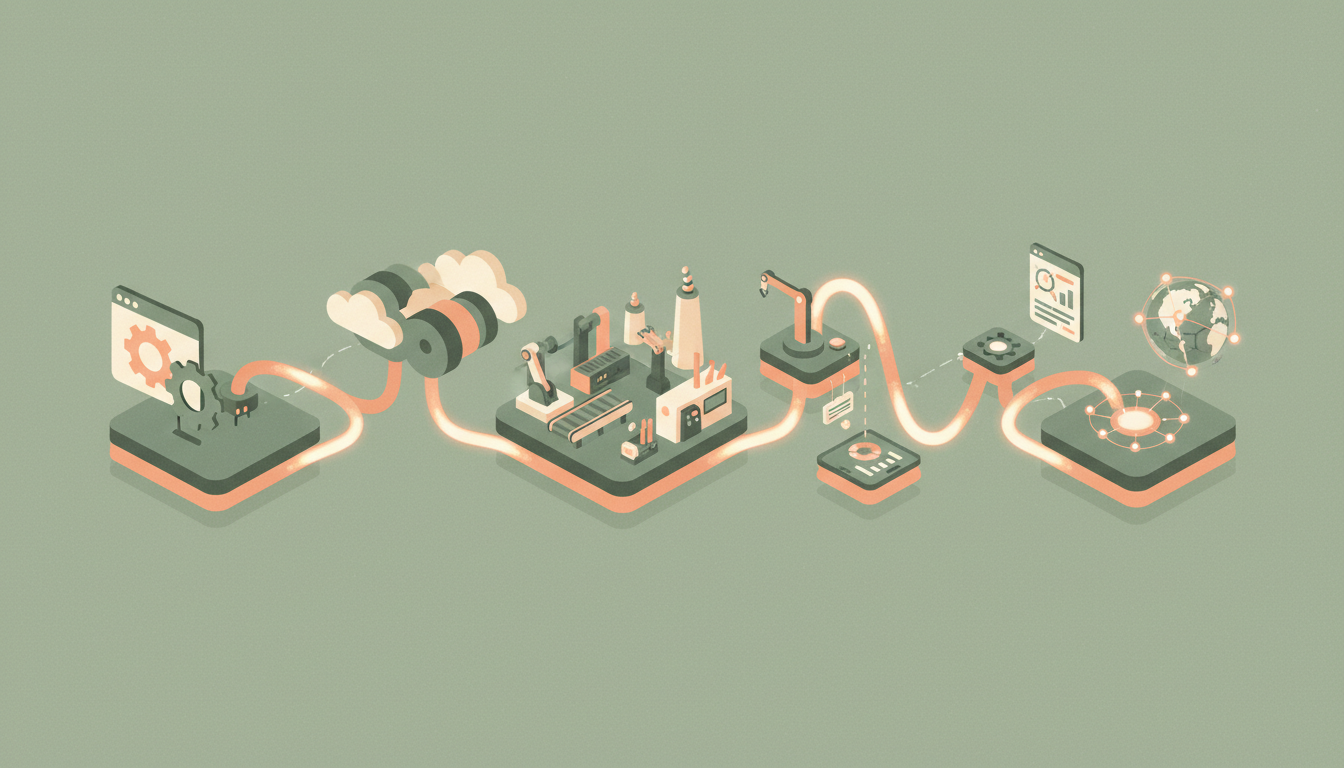

At its core, the digital thread is a communication framework. It’s a single, seamless strand of data that connects historically isolated stages of a product’s life,from initial design and engineering, through manufacturing and production, to service in the field and eventual end-of-life. Its primary purpose is to create data continuity across the entire product lifecycle management (PLM) ecosystem, ensuring that information flows bi-directionally without manual translation, re-entry, or loss of context.

Think of it as the central nervous system for your product data. Without it, your design team’s CAD model, your production team’s machining instructions, and your quality team’s inspection reports exist in separate, unconnected files and systems. The digital thread weaves these disparate data points into a coherent, accessible, and always-up-to-date story.

Core Definition

The digital thread is an authoritative, integrated data backbone that connects and contextualizes information flows across the entire product lifecycle. Unlike traditional data management, which often involves exporting static files (like a PDF drawing or an Excel BOM) and handing them off to the next department, the digital thread maintains live links between all related data.

Traditional data management creates copies. The digital thread maintains connections. In a traditional setup, when an engineer updates a 3D model, someone must manually inform production, update the BOM in the ERP system, and alert procurement. This process is slow and error-prone. With a digital thread, the update in the CAD system is automatically reflected and accessible within the production planning software, the ERP system, and the supplier portal. The change is propagated, traceable, and governed, eliminating version confusion and ensuring everyone is literally on the same page.

Data Flow in Digital Thread

The magic of the digital thread technology lies in its dynamic data flow. Let’s trace how information moves for a simple component, like a custom gear:

- Design & Engineering: A mechanical engineer creates the gear in a CAD system. This model isn’t just geometry; it carries metadata,material specifications, tolerances, and a unique identifier. This data forms the first node on the thread.

- Simulation & Validation: The CAD model is pulled into simulation software for stress analysis. The results are linked back to the original model. If a weakness is found, the engineer updates the CAD file. This update is automatically logged on the thread, and the simulation can be re-run with the new data.

- Process Planning & Manufacturing: The finalized model is accessed by a manufacturing engineer in a CAM system to generate toolpaths for a CNC machine. The thread ensures the CAM system uses the absolute latest revision. The machine code is generated and stored as part of the thread.

- Production Execution: On the shop floor, the CNC machine operator calls up the job. The machine’s performance data,tool wear, cycle times, dimensional checks,is fed back and attached to that specific gear’s data thread.

- Quality Assurance: A quality inspector scans the finished gear’s serial number. The digital thread pulls up the exact design specs and production data. The inspector’s measurement results are appended to the thread, creating a complete quality history.

- Service & End-of-Life: Years later, if that gear fails in the field, a technician scans its serial number. The digital thread provides the full genealogy: original design, manufacturing batch, quality reports, and service history, enabling rapid root-cause analysis and informed repair or recycling decisions.

This closed-loop flow transforms manufacturing data from a series of disconnected snapshots into a living, breathing biography of the product.

Digital Thread vs Digital Twin: Understanding the Differences

A common point of confusion is the relationship between the digital thread and the digital twin. While deeply synergistic, they are distinct technologies serving different, complementary purposes. Mixing them up is like confusing the biography of a person (the thread) with a live, functioning clone used for experimentation (the twin).

Digital Thread is the historical and connective data framework. It is the record of what is and what was,the single source of truth containing all the information generated across the product’s life. It answers questions like: "What revision of this part was used in Lot #247?" or "What were the exact torque settings applied to this engine during assembly?"

Digital Twin is a dynamic, virtual simulation model. It is a living digital representation of a physical asset or system that uses data from the digital thread (and real-time sensor data) to mirror its state, simulate its behavior under different conditions, and predict future performance. It answers questions like: "How will this turbine blade wear over the next 1,000 flight hours?" or "What happens to assembly line throughput if we change Robot A's speed?"

Here’s a clear comparison:

| Feature | Digital Thread | Digital Twin |

|---|---|---|

| Core Function | Data integration, traceability, and continuity. | Simulation, prediction, and real-time mirroring. |

| Primary Focus | The past and present data lineage of an asset. | The present and future behavior of an asset. |

| Nature | Authoritative record-keeping and communication framework. | Dynamic, computational model that learns and adapts. |

| Key Question | "What is the correct, up-to-date information?" | "What will happen if...?" or "Why did this happen?" |

| Data Flow | Bi-directional flow of authoritative data across lifecycle stages. | Feeds on data from the thread and sensors; outputs insights back. |

How They Work in Synergy

The true power in modern manufacturing technologies is unlocked when digital thread and digital twin work together. The digital twin cannot function accurately without the rich, contextual data provided by the digital thread. Conversely, the insights and predictions generated by the digital twin become valuable new data points that are fed back into the digital thread for future reference.

Use Case Example: Predictive Maintenance

1. The digital thread provides the twin with the asset's full history: original design specs, as-built manufacturing data, maintenance logs, and past failure reports.

2. The digital twin ingests this historical data along with real-time sensor data (vibration, temperature). It runs simulations to predict a bearing failure in 14 days.

3. This prediction triggers a work order. The maintenance procedure, parts used, and outcome are all recorded back into the digital thread, enriching the asset's history and making future predictions even more accurate.

This synergy creates a powerful, self-improving loop where data fuels intelligence, and intelligence generates better data.

Top Benefits of Implementing Digital Thread in Manufacturing

Adopting a digital thread is a strategic investment that reshapes manufacturing from a series of discrete operations into a cohesive, intelligent system. The benefits cascade across operations, finance, and innovation.

Operational Efficiency

The most immediate impact of the digital thread is the dramatic streamlining of core manufacturing processes. By eliminating manual data handoffs and searches, companies experience significant reductions in non-value-added time.

Digital thread streamlines manufacturing processes by creating a single point of access for all product information. An aerospace manufacturer implementing a digital thread reduced its engineering change order (ECO) processing time from an average of 35 days to just 4 days. Previously, an ECO required manually updating over a dozen separate documents and systems, with a high risk of omission. With the digital thread, a change in the CAD model automatically triggered updates in linked manufacturing instructions, quality plans, and supplier documentation, with approval workflows built into the thread itself.

This accelerates production cycles and reduces downtime on the shop floor. Machine operators are no longer waiting for clarified drawings or correct files; the latest, approved version is always at their fingertips. When a quality issue arises, traceability is instantaneous. Instead of a multi-day investigation to find which batch used a potentially faulty component, a query through the digital thread can identify all affected units in minutes, enabling precise containment.

Financial Impact

The operational gains translate directly into a healthier bottom line. The financial argument for digital thread is built on cost avoidance, waste reduction, and new revenue opportunities.

Cost benefits are realized through several channels. First, the drastic reduction in errors and rework. One automotive supplier reported a 40% decrease in scrap and rework after implementing a digital thread, as manufacturing always had the correct design data. Second, it optimizes inventory. With precise, connected BOMs and real-time production data, companies can move from broad-brush safety stock to lean, just-in-time inventory models, freeing up significant working capital.

ROI examples often show a payback period of 18-24 months. Consider the savings: reduced prototyping costs (through better virtual validation), shorter time-to-market (which can command premium pricing), and lower warranty and service costs due to higher product quality and better field diagnostics. The long-term financial advantage is scalability. As product complexity grows,with more electronics, software, and customization,the cost of managing data without a digital thread grows exponentially. The digital thread provides a framework that can scale efficiently, avoiding future cost explosions.

Beyond efficiency and cost, the digital thread fosters unprecedented collaboration. Designers can see how their choices impact manufacturability. Service technicians can provide feedback that directly influences the next design iteration. This transparency breaks down departmental walls, leading to more innovative and manufacturable products.

Step-by-Step Guide to Implementing Digital Thread

Implementing a digital thread is a journey, not a weekend project. It requires careful planning, phased execution, and a shift in mindset from managing documents to managing connected data. Here is a practical, step-by-step framework.

Planning Phase

Success begins long before any software is installed. The planning phase is about laying a solid foundation.

-

Assess Your Current State: You cannot build a bridge to the future if you don't know where you're starting from. Conduct a thorough audit of your current data and system infrastructure.

- Map Your Data Flow: Whiteboard your current product lifecycle. Where does data originate (CAD, requirements)? Where does it go (ERP, MES, PLM)? How is it transferred (email, Excel, manual entry)?

- Identify Silos & Pain Points: Pinpoint where delays and errors most frequently occur. Is it during the handoff from engineering to manufacturing? Is it in quality documentation? These are your primary targets.

- Catalog Your Tools: List all software involved (CAD, CAM, ERP, MES, QMS, CMMS). Understand their current integration capabilities.

-

Align Stakeholders & Define Scope: A digital thread impacts everyone. Early and broad stakeholder alignment is critical.

- Secure executive sponsorship to champion the initiative and secure resources.

- Bring together leaders from engineering, manufacturing, quality, IT, and supply chain. Create a shared vision of the "future state."

- Start Small, Think Big: Don't try to thread your entire product portfolio on day one. Choose a pilot project,a new product line or a specific, problematic component. This limits risk and allows for quick wins that build momentum.

-

Choose Your Technology Foundation: You don't necessarily need to rip and replace all your systems. Focus on choosing the right tools for integration and data management.

- Platform Selection: You may need a PLM or IoT platform that can act as the "hub" for your thread. Evaluate platforms based on their open APIs, pre-built connectors for your existing tools, and data modeling capabilities.

- Define the "Golden Thread": Decide what constitutes your authoritative source of truth for each data type. Is the CAD model in System A the "golden" design? Is the BOM in System B the "golden" bill? Clearly define these rules.

Execution Phase

With a plan in place, you move to careful, monitored rollout.

-

Develop & Configure: This is where the digital thread is built.

- Data Modeling: Structure your data in a way that supports connectivity. This often means moving from file-based storage (e.g., a STEP file in a folder) to item-based or model-based definitions, where data is stored as connected attributes in a database.

- Establish Integrations: Use APIs, middleware, or platform connectors to create the live links between your key systems (e.g., CAD to PLM, PLM to ERP). Prioritize integrations based on your pilot scope.

-

Run the Pilot & Train Users: Deploy the threaded environment for your pilot project.

- Train, Don't Just Tell: Comprehensive training is non-negotious. Users must understand not just how to use the new interface, but why the process has changed. Show them how it eliminates their biggest daily frustrations.

- Monitor & Measure: Establish KPIs for the pilot: e.g., "Reduce ECO time by 50%," "Eliminate BOM errors." Closely monitor these and gather user feedback daily.

-

Scale & Optimize: After a successful pilot (typically 3-6 months), begin a phased rollout.

- Refine Your Approach: Incorporate lessons learned from the pilot into your rollout plan for the next product line or business unit.

- Expand the Ecosystem: Gradually add more data sources and systems to the thread, such as supply chain portals or field service management tools.

- Govern and Maintain: Establish a governance council to manage data standards, user access, and the evolution of the digital thread framework. This ensures it remains robust and valuable.

Overcoming Common Challenges: Resistance to change is the biggest hurdle. Address this through constant communication and by involving users in the design process. Technical challenges often involve legacy systems with poor APIs. Sometimes, a tactical replacement or the use of specialized integration tools is the most cost-effective long-term solution.

Real-World Examples of Digital Thread in Action

The theory of digital thread is compelling, but its real value is proven on the factory floor and in the field. Here are how leading industries are leveraging it.

Aerospace & Defense: This sector, with its extreme complexity and regulatory demands, is a pioneer. A major aircraft engine manufacturer uses a digital thread to manage the lifecycle of its engines, which contain tens of thousands of parts. The thread connects design, additive manufacturing parameters, sensor data from test cells, and in-flight performance data. This allows them to perform precise, condition-based maintenance and rapidly certify design changes. The result is a significant increase in engine availability and safety, while reducing maintenance costs.

Automotive: An electric vehicle (EV) startup used a digital thread from day one to manage its breakneck development schedule. The thread connected their CAD systems directly to their factory-floor MES and robotic assembly lines. When a design tweak was made to a battery enclosure for better thermal performance, the updated manufacturing instructions were automatically available to the production robots and the quality inspection stations. This seamless flow was instrumental in achieving their aggressive time-to-market goals, allowing them to iterate rapidly without production missteps.

Industrial Equipment: A manufacturer of large agricultural harvesters implemented a digital thread to solve a chronic issue with service part accuracy. Previously, a field technician might order a replacement hydraulic valve based on the harvester's model year, only to find it didn't fit due to a mid-year running change. By giving technicians mobile access to the digital thread via the machine's serial number, they could see the exact as-built configuration and order the correct part every time. This reduced defects in service and improved customer satisfaction dramatically.

Electronics: A consumer electronics company uses a digital thread to manage the complex relationship between hardware, firmware, and software. A change in a circuit board layout (hardware) is automatically checked against the embedded software code. This prevents costly recalls where a device is shipped with software incompatible with its physical components.

The key insight from these early adopters is universal: start with a clear, painful business problem, not with technology for technology's sake. The digital thread is the means to solve that problem through seamless data integration. The future trend is the expansion of the thread beyond the OEM to include tier-n suppliers and customers, creating a truly collaborative, ecosystem-wide lifecycle view.

Conclusion

The digital thread technology is far more than a new IT system; it is a fundamental re-architecture of how manufacturing information is created, shared, and used. It replaces fragmentation with seamless data integration, guesswork with traceability, and reactive operations with proactive intelligence. By creating a single, authoritative backbone of connected data across the entire product lifecycle management journey, it delivers unprecedented manufacturing efficiency, fosters innovation through better collaboration, and builds a foundation for sustainable competitive advantage in an increasingly complex and digital world.

Key Takeaway: Digital thread technology is revolutionizing manufacturing by enabling seamless data integration across the product lifecycle, leading to unprecedented efficiency, innovation, and competitive advantage.

Ready to transform your manufacturing process? This guide has outlined the "what," "why," and "how." The next step is to assess your own operations. Explore more in-depth resources on specific integration strategies and platform comparisons at ManufactureNow, or contact us for personalized guidance and consultations tailored to your unique manufacturing challenges.

Written with LLaMaRush ❤️